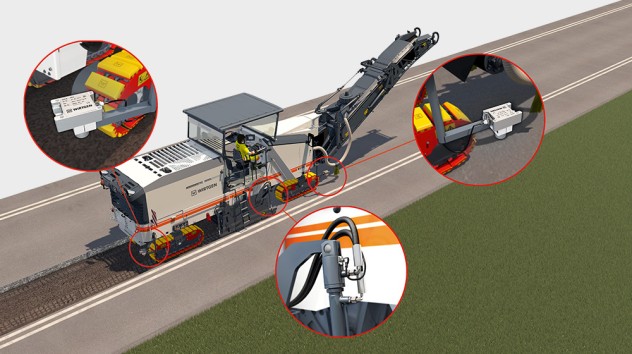

WIRTGEN sensors and scanning equipment

The transducers

Deviations from the target value are

picked up by the sensors and calculated by the levelling system, which

then automatically transmits a corrective value to the machine.

Different sensors are used for different applications depending on the

reference used (e.g. pavement surface, kerb or stringline).

The sensors are generally available for all product divisions and machine types and are used to suit the specific application

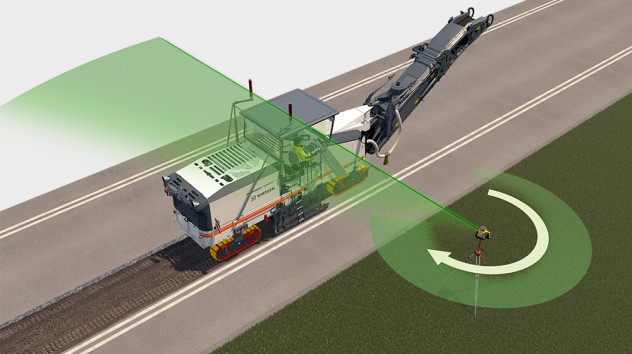

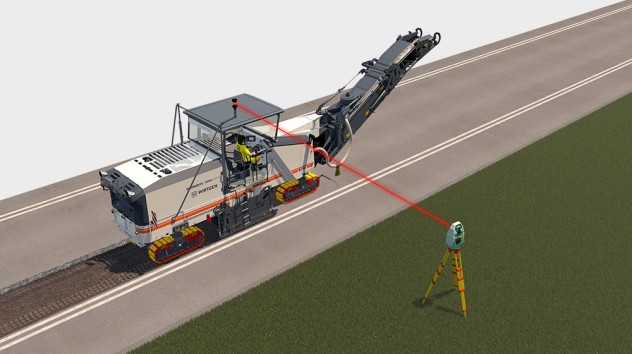

Laser sensor: With laser levelling methods, laser sensors on the machine receive signals from a rotating laser beam.

|

|

| Cable

sensor: A mechanical cable sensor connected to the side plate with a

wire determines the difference between the side plate and machine

chassis. |

Hydraulic

cylinder sensor: Path sensors in the hydraulic cylinder determine the

difference between the side plate and machine chassis. |

|

|

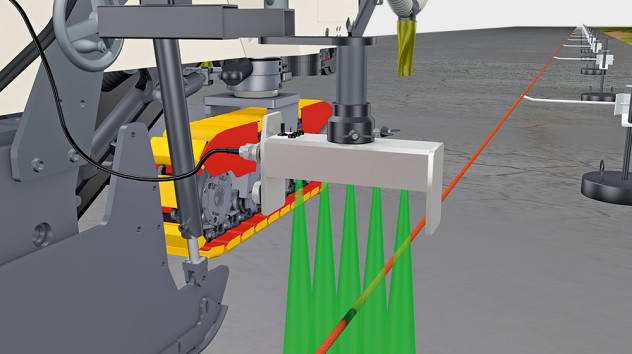

| Ultrasonic sensor: The non-contact ultrasonic sensor determines the distance of the machine to the reference surface. |

|

|

|

| Sonic

Ski sensor: The non-contact Sonic Ski sensor determines the distance of

the machine to the reference surface. This may also be a stringline. |

Multiplex

systems: Multiplex systems combine multiple sensors on one or both

machine sides (e.g. cable, ultrasonic, cylinder sensor). Using the

average value of the connected sensors, the current milling depth is

calculated with high precision. |

|

|

> Laser sensor: With laser levelling methods, laser sensors on the machine receive signals from a rotating laser beam.

|

3D

sensor: A total station focuses a receiver prism, from which it

calculates the position and height of the cold milling machine. This

data is transferred to the 3D computer for further processing.

|

Công nghệ khác

WIRTGEN levelling systems