WITOS FleetView - And everything runs smoothly

WITOS FleetView gets the machines of WIRTGEN, VÖGELE and HAMM

communicating: every unforeseen fault, along with every due inspection,

is displayed on the WITOS FleetView web application.

A penny saved is a penny earned. WITOS FleetView is a must-have for

anyone who takes this old proverb to heart. That’s because the

telematics solution from the WIRTGEN GROUP offers users and machine

operators a wide range of advantages that translate into hard cash. A

real-life example confirms: GSI-Asphalt, a medium-sized enterprise, have

been relying on WITOS FleetView in conjunction with the Smart Service

agreement for many years now. Both services guarantee maximum machine

availability – enhancing the cost-efficiency and value retention of the

machinery.

A powerful medium-sized enterprise specializing in fibre-optic expansion

GSI-Asphalt is a successful SME that has been growing steadily for

years. There are good reasons for this: efficient processes, a high

quality standard and a business model that is geared to the local

authority sector, particularly the construction of utility lines and the

expansion of the fibre-optic network. The modern machine fleet of the

WIRTGEN GROUP – and the WITOS FleetView and Smart Service packages –

make a key contribution to the company’s efficiency and quality. Indeed,

these two strategic instruments enable GSI-Asphalt to get more out of

their investment: “The due inspections and service intervals are

scheduled by the WIRTGEN GROUP for all the machines,” explains Werner

Aicher, Managing Director of GSI-Asphalt, highlighting a key advantage

of WITOS FleetView. The telematics solution enables the WIRTGEN GROUP to

analyse service-related parameters such as operating hours and send

notifications of upcoming inspection services. It goes without saying

that the data are also available to the customer and the customer’s

staff too, where appropriate.

Perfect interplay between the customer GSI-Asphalt and the WIRTGEN

GROUP: the machine fleet automatically transmits service-related data to

the customer and the WIRTGEN GROUP sales and service company via the

WITOS FleetView telematics solution. The subsidiary in Augsburg then

schedules the service appointments in consultation with GSI-Asphalt.

WITOS FleetView slashes downtimes

“The telematics solution is straightforward, and we don’t have to keep

thinking about our machines,” says Aicher. “The system has significantly

increased the capacity utilization of our machine park. What’s more, we

can always be confident that there will be no avoidable trips to the

workshop during a construction project. As a result, our operations can

be planned more effectively and are more cost-efficient, too, because we

always have three weeks’ notice ahead of service appointments, enabling

us to reschedule machines if necessary or make use of substitute

WIRTGEN GROUP machines. So there’s no disruption to the work.” And once a

machine is due for servicing, the Smart Service helps contractor

GSI-Asphalt keep costs down. Anyone using a variety of machines from

WIRTGEN, VÖGELE and HAMM or – as in the case of GSI-Asphalt – with a

fleet made up entirely of WIRTGEN GROUP products, enjoys further

benefits: the central contact at the relevant WIRTGEN GROUP subsidiary

can coordinate a single service or maintenance appointment for multiple

WIRTGEN, VÖGELE and HAMM machines. This further increases machine

availability.

WITOS FleetView at a glance

WITOS stands for “WIRTGEN GROUP

Telematics and On-site Solutions” and is the name given to the software

product family of the WIRTGEN GROUP that supports customers, operators

and users above and beyond the machine hardware.

WITOS FleetView makes fleet and service management for WIRTGEN, VÖGELE

and HAMM machines even more efficient, because the system-based

visualization and analysis of machine and position data give machine

managers and users an overview of their machine fleet at all times.

While the Smart Service agreement provides for regular inspections in

accordance with the instruction manual, WITOS FleetView additionally

supports proactive maintenance planning and a rapid response in the

event of faults.

How WITOS FleetView works

The telematics control unit (TCU) installed in the machines collects,

compresses and stores the machine data. The data are then sent in

encrypted form via GSM to the WIRTGEN GROUP data centre, where they are

analysed and made available to the customer

WITOS FleetView – The functions in detail

WITOS FleetView supplies the data in a user-friendly web application

with clear and well organized submenus. An overview of the most

important functions:

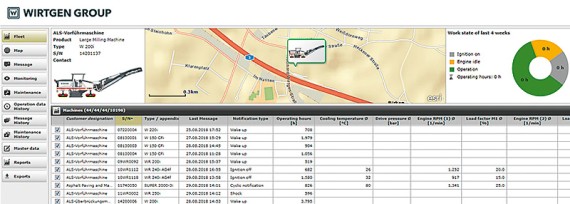

Fleet:

This menu provides a compact overview of

the current operating status of a company’s machine fleet. One or

several machines can be selected for more detailed views and analyses.

Map

The map view shows the current location

of one or several machines. The machine path function enables you to

track the route that the machine takes during operation and transport.

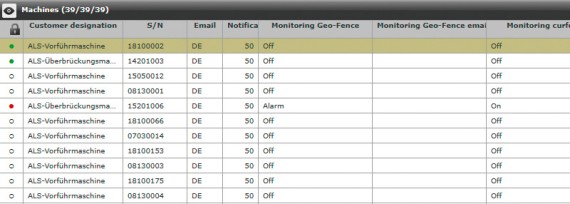

Monitoring

With these functions, it is possible to

define times when and places where the machines of a fleet are permitted

to operate. If monitoring protection is activated, operators are given

immediate notification by e-mail in the event of unauthorized access to

the machine. Notifications can be defined for alarms and faults as well

as maintenance dates.

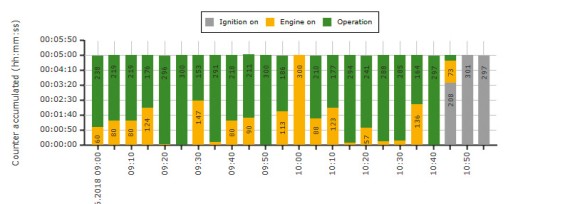

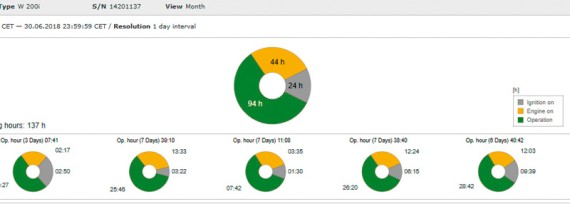

Operation data / History

The history view allows operational and

position data to be displayed for the machines over a freely definable

period, in a clear and easily readable layout. These data can also be

exported.

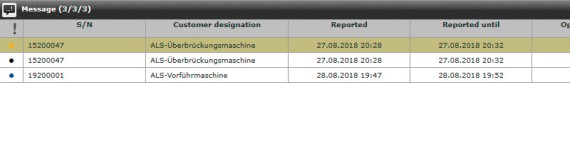

Messages / History

All current and past messages from the

machines at a glance: the history view can be used to generate an

individually defined summary. All messages are displayed and described

just as they appear on the machines. The clear message categorization

and the documentation provide information on the service status of the

machines.

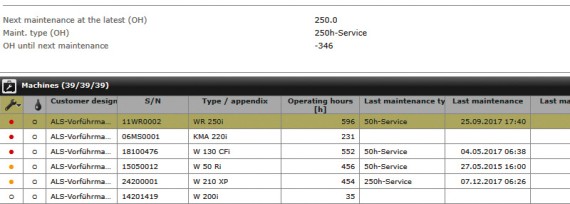

Maintenance / History

The history view of the maintenance

section contains all the information required to ensure optimally

maintained machinery. Be it information on the type and scheduling of

upcoming maintenance work or maintenance reports on previous workshop

visits, the maintenance functions reliably ensure that the entire

machine fleet remains operational.

Reports

Eight predefined reports on the machine

capacity utilizations and the fleet overview are available to the user.

These can be displayed as daily, weekly, monthly or annual overviews and

can also be exported.

One-stop service

With WITOS FleetView, servicing has become a more automatic process for

GSI-Asphalt – but without losing the personal touch. Thomas Weber of the

WIRTGEN GROUP subsidiary in Augsburg has for years been a dedicated

point of contact for GSI-Asphalt, attending to all concerns – which of

course extend beyond the service information provided by WITOS

FleetView. “We genuinely profit from the rapid response times, even when

we have questions or want to make use of the application-specific

advice. This bolsters our view of the WIRTGEN GROUP as a true partner

whose loyal support can be relied on,” says Werner Aicher.

Công nghệ khác

VÖGELE Get the Job Done Accurate to the Millimetre

“AutoSet Plus” is Quality Assurance at the Press of a Button

SprayJet versus Conventional Paving with Pre-Spraying of Emulsion