VÖGELE RoadScan

The scanning and documentation of the freshly paved asphalt‘s temperature is already specified in tenders in several markets, and in others there are definitive plans to implement this. With its new RoadScan temperature measurement system, VÖGELE deliver the technology required for the job.

And that‘s not all: the system helps road construction teams to continuously monitor the temperature of the supplied mix. What is more, after completion of the construction job, contractors can furnish detailed evidence that the temperature was maintained within the correct range — thanks to the recorded GPS data, including precise tracking.

The highlights of VÖGELE RoadScan

- Area-wide temperature measurement across the entire pave width up to 10m

- Real-time display on the paver operator‘s ErgoPlus 3 console to help the paving team achieve a high-quality asphalt pavement

- Simple mounting of the measuring unit without any adjustment (Plug & Play)

- Reliable technology thanks to a robust design with no moving parts

- High-precision GPS receiver integrated in RoadScan for recording exact position data

- Recording of influencing parameters for important analysis data, such as the base temperature before paving and weather data

High-precision infrared camera with 100% measurement coverage

The high-precision infrared camera is the key component of the VÖGELE RoadScan system. It scans the asphalt pavement behind the screed over the entire area. The housing of the infrared camera also accommodates a high-precision GPS receiver. It records the exact position of the temperature data. In addition to the position, the external influencing parameters are also documented. A pyrometer mounted in front of the undercarriage measures the base temperature before paving. A weather station is available upon request.

| Along with the asphalt temperature, a weather station can also document the wind speed, wind direction, ambient temperature, air pressure and humidity. |

|

|

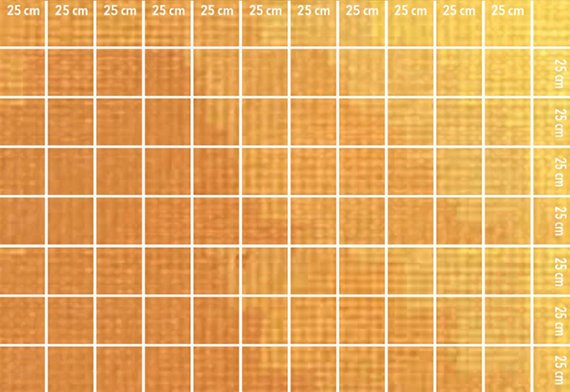

| The measuring width of 10m comprises 40 grids of 25 x 25 cm-sized tiles. Each of these tiles contains up to 16 single measuring points which are used to calculate a mean value. The measurable temperature range lies between 0°C and 250°C with a tolerance of only ±2°C. |

|

|

Simple operation thanks to integration into ErgoPlus 3

Intuitive operation is a VÖGELE feature that is also a benefit for the user of the RoadScan system. This already becomes evident during mounting: before use, the measuring unit is simply installed on the roof of the VÖGELE ”Dash 3“ paver and requires no further adjustments. It is immediately ready for operation as soon as it is connected.

The system is conveniently activated from the paver operator‘s ErgoPlus 3 console. The operator can read off the currently scanned temperatures, which are clearly visualised on the colour display as thermal images. The data is transferred in real time.

As a result, any deviation from the specified temperature of the freshly paved asphalt is detected immediately and can be quickly remedied. This makes the VÖGELE RoadScan system an effective instrument for ensuring high paving quality — without unduly increasing the paving team‘s work load.

Analysis and documentation

The measured data is saved by RoadScan in the paver operator‘s ErgoPlus 3 console. After paving, this data can be read off via an external data storage device. At the same time, VÖGELE has taken effective measures to protect the data: a specially designed memory stick communicates with a VÖGELE interface on the paver operator‘s ErgoPlus 3 console and this, in turn, transfers the data in encrypted form. The data is analysed in the office with the RoadScan Analysis web application.

This permits objective evaluation of the construction job. Thanks to intelligible and clearly arranged graphs and charts the job site can be analysed on the basis of the recorded temperature data and they allow for filtering measurements according to existing specifications.

The use of the VÖGELE RoadScan system with the innovative WITOS Paving process management solution offers a number of additional analysis options.

Công nghệ khác

VÖGELE Get the Job Done Accurate to the Millimetre

“AutoSet Plus” is Quality Assurance at the Press of a Button

SprayJet versus Conventional Paving with Pre-Spraying of Emulsion